The Importance of Thermal Cameras in Maintenance

22.01.2025

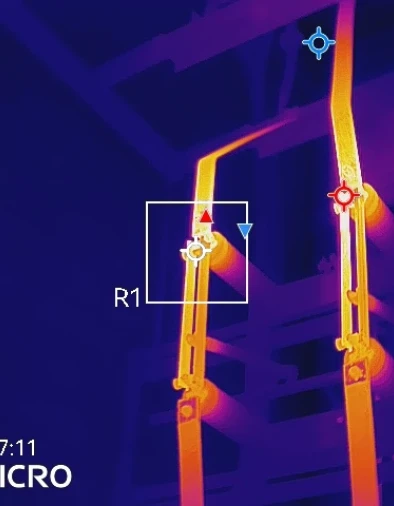

Use of Thermal Cameras in Electrical Systems

Thermal imagers are devices used to detect potential problems by visualizing temperature changes in electrical systems. Electrical components often show a temperature rise before they fail. By detecting these temperature rises, thermal cameras allow for the early identification of faults and maintenance needs.

Benefits of Thermal Cameras in Electrical Maintenance

1. Early Detection and Preventive Care

Thermal imagers help to detect faults in electrical systems early. High temperatures can often indicate poor connections, overloads or equipment failures. Regular scans with a thermal imager allow such potential problems to be identified in advance and necessary maintenance can be carried out before equipment fails.

2. Safety

Overheating of electrical systems can lead to the risk of fire. Thermal cameras play a critical role in minimizing this risk. By instantly detecting temperature rises, they help prevent safety hazards. This is important for the safety of both equipment and workers.

3. Energy Efficiency

Thermal cameras contribute to improving energy efficiency by detecting energy losses. For example, overheating of electrical components can lead to energy losses. When these losses are detected and eliminated with thermal cameras, the systems operate more efficiently.

4. Cost Savings

Preventive maintenance prevents major breakdowns and system shutdowns. Regular inspections with thermal cameras help prevent unexpected failures and the high costs they can bring. This results in significant cost savings in the long run.

5. Fast and Contactless Inspection

Thermal imagers allow non-contact and fast inspection of electrical systems. This is a great advantage, especially in hard-to-access or hazardous areas. Furthermore, scans can be performed even during operation, without the need to stop the system.

Which problems can be detected with a thermal camera?

The main problems that can be detected in electrical systems with thermal cameras are:

Loose or poor connections

Overloaded circuits

Unbalanced phase loading

Overheating engines and generators

Worn or damaged insulation materials

Overheating in distribution panels

Conclusion

Thermal cameras have become an indispensable tool in the maintenance of electrical systems. Offering many advantages such as early detection, safety, energy efficiency, cost savings and rapid inspection, thermal cameras play a critical role in improving the safety and efficiency of electrical systems. Regular thermal scans of electrical systems enable early identification of potential faults, ensuring an uninterrupted flow of energy and a safe working environment.

Similar Blogs

Subscribe to our newsletter

Don't Miss the Opportunities

Telephone

+90 216 206 06 50

.png)